Established in 2005 in Shenzhen, YOUNGPOOL Technologies has established itself as a reputable Original Equipment Manufacturer (OEM) and supplier of word-class PCBA equipment in the electronics manufacturing industry. YOUNGPOOL is a member of SMT Commitee of Guangdong Electronics Society and Shenzhen Intelligent Equipment Industry Association.

In 2016, YOUNGPOOL has invested and established its own R&D department to independently design, develop, innovate (IDDI) solutions in the Screen Printing, SMT Splicing, Conformal Coating Degassing and Laser Marking Technologies to provide customers the ability to reduce the cost of equipment introduction, effectively improve yield and maximize production efficiency.

Automatic Slicing Machines

Automatic splicing machine is an integral part of the modern MES (Manufacturing Execution System) in the SMT factory. Integration requires equipment and the MES to work seamlessly, and also requires the equipment to function with a high degree of automation.

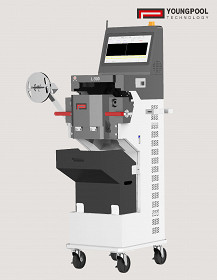

L-900 SMT Multi-function Splicing Systems

L-900 Automatic splicing machine delivers unsurpassed splicing reliability to drive improved yields and utilization with its seamless integration with MES and high degree of automation.

8mm/12mm/16mm/24mm Splicing machine with superior adhesive strength

Designed for the automatic production line of SMT placement machine. For paper tape and plastic tape with same specification, it can realize automatic correction and splicing of two rolls of tapes with a width of 8mm to 24mm. In the process of splicing, the equipment can automatically realize accurate cutting and splicing, and automatically connect the head and tail of two rolls of tapes by high adhesion film, so as to realize continuous production.

Key Features

- Automatic splicing for 8\12\16\24mm width carrier tapes

- Up to 98% FPY

- Enhanced splicing reliabiltiy with its superior adhesive strength in comparison with traditional splice tape connector

- Bluetooth and Wi-Fi connectivity to the factory MES

- Continuous operation for up to 12-16 hours once fully charged

- Vision inspection to identify and automatically cut off empty leader tape

- Incorporation of intelligent validation system to prevent operator errors

Other Features

- Easily operate the machine through its highly automated and intuitive graphic interface (GUI)

- Ergonomic design and power-assisted (motor powered) wheels makes it easy to use and faciliate movement on shop floor

- Supports wireless scanners

- Paper and plastic tapes applicable

- Optional label printer to facilitate material management

L-3 SMT Auto Splicing System

Youngpool Technology's L-3 Automatic Splicing Machine has been developed as a solution to resolve common challenges such as management of operations systematically, integration of traceability information with the MES to achieve higher productivity within SMT factories. The L-3 helps to improve outgoing quality, enhance management via MES, and reduce operating cost.

Easy to operate, low requirement splicing machine to improve reloading efficiency

L-3 Automatic Splicing Machine is easy to operate and has low requirements for workers, and it is stable and reliable, which can greatly improve reloading efficiency, save manpower, improve production efficiency, and eliminate problems like poor quality and low reliability caused by manual splicing.

Key Features

- Dedicated 8mm carrier tape splicing (01005 capable)

- Carrier tape thickness 0.25–1.4mm (paper) and 0.25-2.5mm (embossed) applicable

- First Pass Yield at 98% or above/ Up to 98% FPY

- Capable of MES integration, connectivity via Bluetooth and Wi-Fi

- Battery can support 12-16 hours of continuous operation

- Vision inspection to identify and automatically cut off empty leader tape

- Validation function available in both stand-alone and online mode

- Empty-pocket detection using vision inspection

Other Features

Easily operate the machine through its highly automated and intuitive graphic interface (GUI)

Ergonomic design and power-assisted (motor powered) wheels makes it easy to use and facilitate movement on shop floor

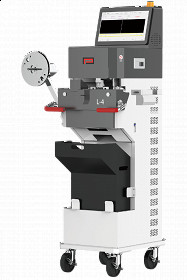

L-4 Automatic SMT Splicing Machine

Youngpool Technology's L-4 Automatic Splicing Machine has been developed as a solution to managing operations systematically and integrating traceability information into the Manufacturing execution System (MES) to achieve higher productivity. The L-3 helps to improve outgoing quality, enhance management via MES, and reduce operating cost.

Achieve higher productivity within today's SMT factories

Youngpool Technology's L-4 Automatic Splicing Machine L-4 is designed for the automatic production line of SMT placement machine. For paper tape and plastic tape with same specification, it can realize automatic correction and splicing of two rolls of tapes with a width of 8mm. In the process of splicing, the equipment can automatically realize accurate cutting and splicing, and automatically connect the head and tail of two rolls of tapes by high adhesion film, so as to realize continuous production.

Key Features

- First Pass Yield at 98% or above/ Up to 98% FPY

- Applicable carrier tape thickness : 0.25 - 2.5mm (carrier material dependent)

- Bluetooth and Wi-Fi connectivity to the factory MES

- Can support 12-16 hours of continuous operation

- Validation function available in both stand-alone and online mode

- Empty-pocket detection using vision inspection

Other Features

- Easily operate the machine through its highly automated and intuitive graphic interface (GUI)

- Ergonomic design, compact size, light-weight and power-assisted (motor powered) wheels makes it easy to use and facilitate movement on shop floor