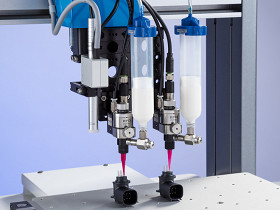

Nordson EFD dispensing robots bring repeatability and precision to your automated dispensing systems and assembly operations. Specially designed, Nordson EFD dispensing robots are compatible with all of our syringe-based and valve-based automated and non-automated dispensing systems and are suitable for a wide range of applications, from inline to batch dispensing.

3D and 4D applications include dots, lines, potting, damming, filling, underfilling, encapsulation, sealing, coating, and jetting. Benefits include greater part production capacity, reduced manufacturing time, consistent accuracy over rough and uneven surfaces, and improved product quality.

3-Axis Automated Fluid Dispensing Robot

3-Axis PROX / PROPlus / PRO Series Automated Fluid Dispensing Robot

Most advanced automated dispensing system, designed and configured for precision and simplified usability.

Delivers best-in-class dispensing performance and process control with closed-loop encoding and simplified, intuitive setup. Benefit from improved product quality and yield while tackling more complex projects that require very precise dispensing and fluid placement.

- The only system that includes specialized DispenseMotion™ software with a fully integrated CCD smart vision camera and three types of feedback – contact, optical, and non-contact laser height sensing

- Specialized software is designed to optimize the performance of PICO® and Liquidyn® jet valve systems. Fiducial recognition allows for multiple image captures for higher resolution offset.

PROPlus Series

- Best-in-class repeatability and speed (PROPlus +/-0.003 mm)

- Dual linear guide, advanced servomotor, and ball screw actuation

Features

- Simplified setup and programming

- On-screen preview and confirmation of the dispense path

- Constant closed-loop feedback

- Streamlined file import and conversion

3-Axis EV Series Automated Fluid Dispensing Robot

Uses visual placement and simple intuitive programming to boost production in any manufacturing process.

The EV Series automated fluid dispensing system is a tabletop robot that delivers easy automation for precise fluid applications with proprietary dispensing software and a simple vision pencil camera.

Features

- Specialized vision-guided DispenseMotion™ software and pencil camera make the EV Series easy to setup and program.

- True 3D motion control makes programming dots, lines, circles, arcs, and compound arcs fast and simple. Mark recognition allows easy part alignment, eliminating the need for precise fixturing.

Benefits

- Save considerable amount of programming time with DXF Import

- Faster cycle and batch times

- Easy integration

- Improved quality control

3-Axis GVPlus / GV Series Automated Fluid Dispensing Robot

The vision-guided GVPlus and GV Series gantry robots work as standalone systems or as part of fully automated solutions. The GVPlus supports heavier arm tooling and improved positional repeatability at ± 0.008 mm vs. ± 0.02 for the GV Series. Working envelopes range from 400 mm to 800 mm for precise fluid dispensing onto substrates requiring large work envelopes without sacrificing repeatability.

Features

- Simplified setup and programming with EFD’s advanced vision-guided DispenseMotion software

- CCD smart vision camera or simple pencil camera

- True, three-dimensional motion control

- Work envelopes as large as 800 mm

- Unlimited workpiece payload

Benefits

- Market-leading dimensional positioning accuracy and deposit placement repeatability

- Unlimited workpiece payload provides full range of dispensing application opportunities

- Streamlines training of in-house operators

- Seamless integration into any manufacturing operation

- Reduced production, material, and ownership costs

- Ideal for conveyer-fed automation

3-Axis E Series Automated Fluid Dispensing Robot

The E Series automated fluid dispensing system is a desktop robot that features a simple-to-use Teach Pendant for quick setup and easy programming.

- Available in three sizes, from 200 x 200 mm to 500 x 500 mm, the it adapts to a wide range of working envelopes.

- True 3D motion control makes programming dots, lines, circles, arcs, and compound arcs easier.

- Can work as a standalone system or as a key part of an automated solution and is easily integrated into in-line transfer systems, rotary tables, and pallet assembly lines.

4-Axis Automated Fluid Dispensing Robot

4-Axis PROPlus Series Automated Fluid Dispensing Robot

Nordson EFD’s 4-axis PROPlus automated fluid dispensing system features a rotating table that reduces vibration, improves repeatability, and creates less wear and tear on the robot than standard 4-axis robots that use a rotating head. It also allows users to mount taller, heavier dispensing devices on the robot head for added versatility.

The modular design allows for both 4-axis and 3-axis configurations for added flexibility with a wide range of fluid dispensing applications. It can accommodate dispensing tips as small as 33 ga, ideal for small, intricate medical device and electronic parts.

It includes the same features as our PROPlus Series including specialized DispenseMotion™ software, integrated CCD vision, and optional laser height detection, and best-in-class X, Y, and Z-axis repeatability of ±0.003 mm. Unique to the 4-axis PROPlus is R-axis repeatability of 0.005°, providing the perfect solution for precise 360° dispensing.

Features

- Modular design for 3- and 4-axis applications

- Dual linear guide, advanced servomotor, and ball screw actuation

- Simplified setup and programming

- On-screen preview and confirmation of the dispense path

- Constant closed-loop feedback

Benefits

- Best-in-class X, Y, and Z-axis repeatability and speed at ±0.003 mm and R-axis repeatability of 0.005°

- Improved quality and consistency

- Rotating table creates less vibration that reduces wear and tear and improves longevity of the robot

- Easy integration into existing manufacturing operations

- Faster speed for higher product output

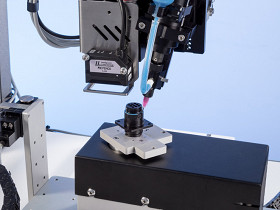

4-Axis RV Series Automated Fluid Dispensing Robot

The RV Series automated fluid dispensing system features proprietary DispenseMotion™ software and a fully integrated CCD smart vision camera for best-in-class fluid placement accuracy and control at any angle along the 360° rotational plane.

- The RV Series is a tabletop or desktop robot that also features single point needle adjustment and best-in-class dispense repeatability at +/- 8 μm. Platforms range from 300 x 300 mm to 620 x 500 mm, making them an ideal solution for batching or critical industrial dispensing applications.

- Specialized vision-guided dispensing software and an integrated CCD camera make the RV quick to set up and easy to program. True three-dimensional motion control provides easy programming of dots, lines, circles, arcs, compound arcs, and patterns on different planes.

Features

- Modular design for 3- and 4-axis applications

- Dual linear guide, advanced servomotor, and ball screw actuation

- Simplified setup and programming

- On-screen preview and confirmation of the dispense path

- Constant closed-loop feedback

Benefits

- Best-in-class X, Y, and Z-axis repeatability and speed at ±0.003 mm and R-axis repeatability of 0.005°

- Improved quality and consistency

- Rotating table creates less vibration that reduces wear and tear and improves longevity of the robot

- Easy integration into existing manufacturing operations

- Faster speed for higher product output

4-Axis R Series Automated Fluid Dispensing Robot

The R Series automated fluid dispensing system features specialized TeachMotion™ Teach Pendant software for market-leading repeatability and accuracy in fluid placement and positioning.

- Its fourth axis allows for dispensing at any angle along the 360° rotation plane. With custom dispensing software, it’s easy to set up and program the system for dispensing applications in less time.

- True 3D motion control simplifies programming of dots, lines, circles, arcs, compound arcs, and patterns on different planes. Simultaneous X and Y movement during R rotation makes it necessary to program only the R axis for true point programming.

- The R Series features best-in-class repeatability at +/- 8 µm for higher throughput yields.

Features

- Simplified setup and programming via Teach Pendant

- Easy USB file upload and download

- Built-in tip recalibration sequence for easy dispense tip change alignment

- 360° rotation for ID and OD dispensing

Benefits

- Market-leading dimensional positioning accuracy and deposit placement repeatability

- Easier setup and programming

- Faster cycle and batch times

- Seamless integration into any manufacturing operation